- Home

- Products & Services

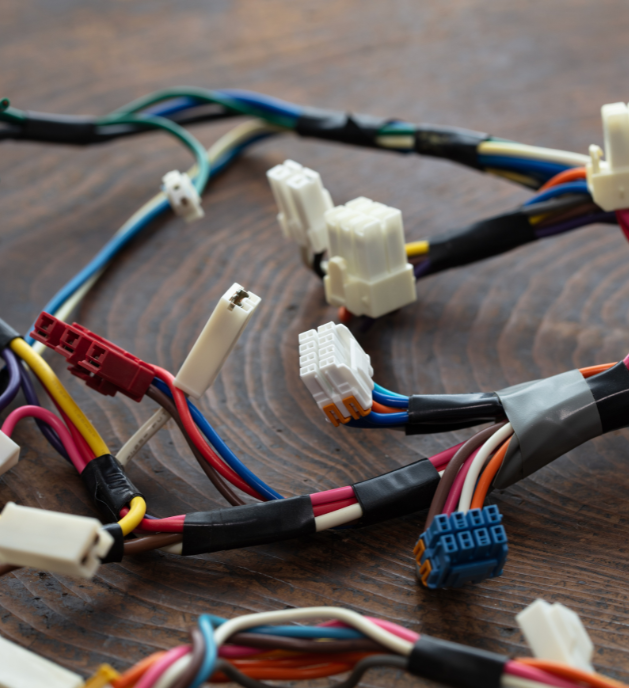

- Cable Assemblies

- Electro-Mechanical Assemblies

- Box Builds

- Wire Harnesses

- Wire Marking

- Wire & Cable Processing

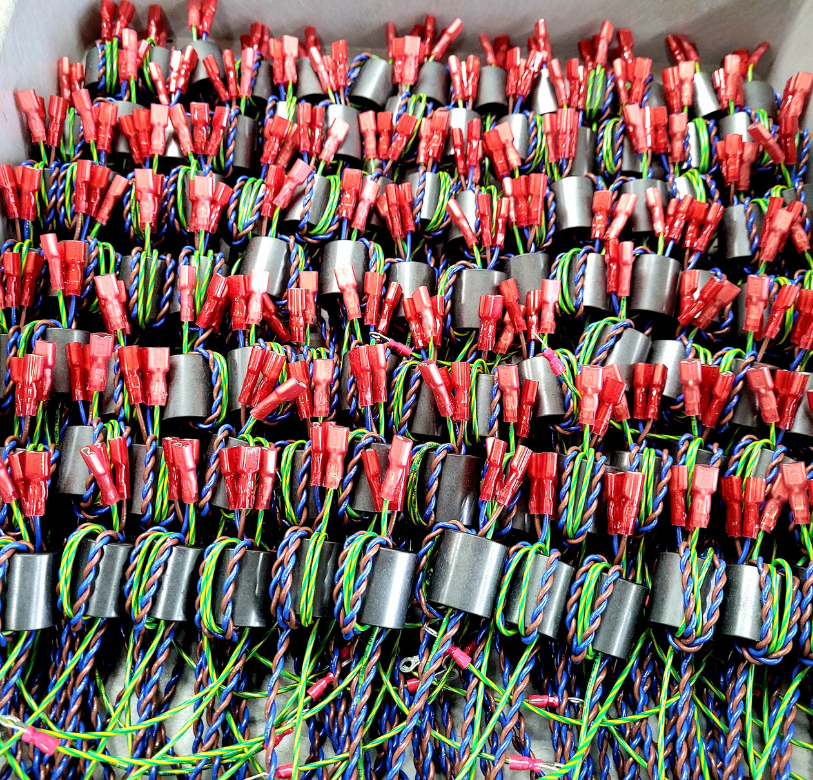

- Wire & Cable Lead Making

- Overmolding

- Overbraiding

- D-Subminiature Assemblies

- Ribbon Cable Assemblies

- Battery Cable Assemblies

- Coaxial Cable Assemblies

- Control Cable Assemblies

- Breakout Boxes

- Control Panel Wiring/Manufacturing

- View All Products & Services

- Industries Served

- About Us

- Contact Us

Why Outsource to Data Cable

Original equipment manufacturers need every available advantage to remain competitive and keep business progressing forward in today’s dynamic environment.

Times have changed. OEMs no longer retain 100% of the responsibility of manufacturing their own custom cable assemblies, custom wire harnesses, electro-mechanical assemblies or box builds in-house. They outsource their cable assembly manufacturing needs. Why? This is a non-core function that brings large costs, massive challenges, and regularly falls short of meeting business needs and expectations.

Outsourcing to a custom wire harness assembly manufacturer like Data Cable, enables OEMs to:

- Better manage their budgets.

- Reduce costs, like payroll, inventory, warehousing, equipment and tools.

- Improve reliability, efficiency, safety & quality of their interconnection components and parts.

- Benefit from customized design that meets their unique and specific needs.

- Regain control over their business by freeing up resources (money, people and time) to focus on what really matters - their core competencies!

Why Choose Data Cable?

Teaming with Data Cable brings you a proven track record in which customer expectations are always met and exceeded. It means:

- Solutions you can count on to increase your productivity, profits & yield. Learn more about our products and services.

- Specialized knowledge and expertise.

- Skilled & experienced staff to design, build and test.

- Technicians on call for expert consultation whenever you need it.

- Established processes and procedures in place - no learning curve required.

- Quality systems continuously pushing for absolute perfection - every single wire and cable that we process is inspected before it leaves our facility.

- A production department tuned to the highest level of quality attainable.

- Ongoing investment in technology and equipment.

- Inventory management.

- Manufacturing space.

- Through the value-added services we make available to our OEM customers.

- CSA Certification, UL Recognition, and ISO 9001:2015 Quality Management Standard all contribute to the consistent high quality of Data Cable’s custom cable assemblies and box builds. Learn more about our regulatory and environmental requirements and safety standards.